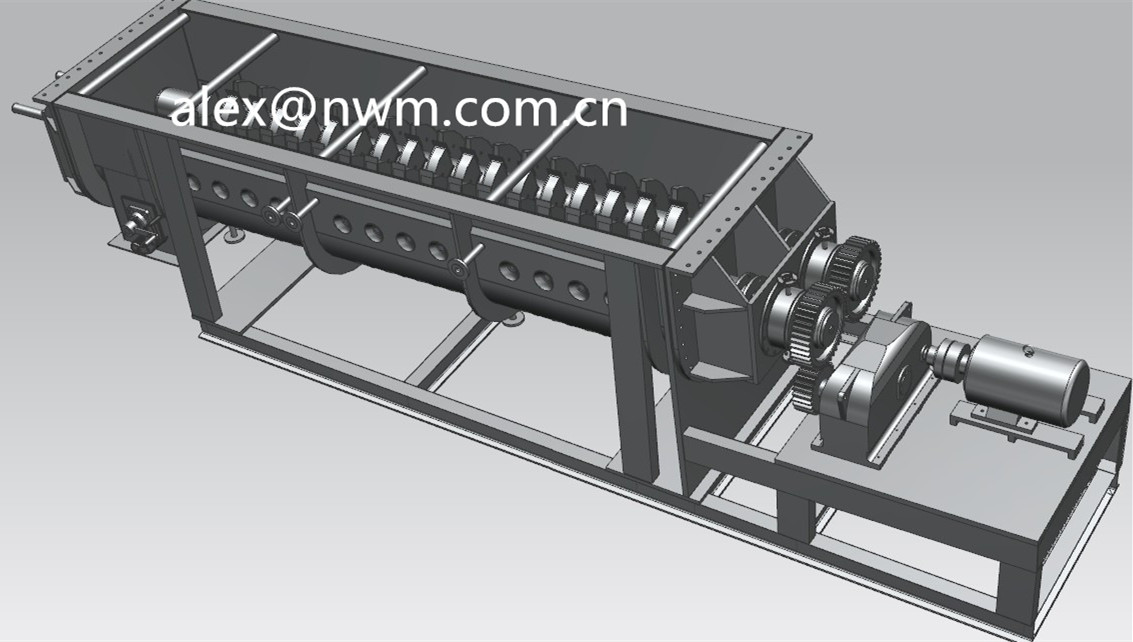

Hollow shaft Blade (paddle) dryer

Description

The hollow shaft of the paddle dryer is densely arranged with wedge-shaped hollow blades. The heat medium flows through the blades by the hollow shaft to heat the blades. The material advances in the vessel at a uniform speed due to the design angle of the blades and absorbs the heat from the wall of the blade. The moisture is evaporated and pumped away by the draught fan.

The effective heat transferring area per unit volume is big, heat medium temperature from -40oC to 320oC, can be water vapor, may also be liquid -type: such as water, oil and so on.

It is Indirect conduction heating, no air take away the heat, high heating efficiency, the only heating loss just be radiating through insulation layer. Wedged surface can clear itself, the relative movement between the material particle and wedged surface will occur scrub, so in operation can maintain a clean heat transfer surfaces.

The shell of paddle dryer is Ω-shape, normally there are 2 to 4 hollow mixing shafts. There is sealing end plate and cover, can avoid the dust leakage to ensure the best heat transfer.

Character

1) Low energy consumption: As a result of indirect heating, no much air take away the heating, the outer wall has insulation layer, the heat efficiency can be up to 90%. For slurry, evaporating 1kg of water just need 1.2kg vapor.

2) cheap investment: it has huge effective heat transfer surface area per unit, reduce treatment time, let the machine size become small, so It greatly reduces the construction area and building space.

3) wide range of materials handling: can use different types of media, not only can treat heat-sensitive materials, but also handle high-temperature materials. Common medias are: water vapor, thermal oil, hot water, cooling water and so on.

4) flexible operation method: Can be continuous operation or intermittent operation, can be applied in many fields.

5)Low environmental pollution: don’t use air to dry material, dust material entrainment is rare. Small solvent evaporation, easy to treat. For contaminated materials or solvent recovery conditions, closed-loop can be used.

6)Cheap operating costs: Low-speed mixing and reasonable structure, Low wear, low maintenance costs. For normal operation, just only 1 person / day.

7)Stable operation: Due to the special compression-expansion stirring of the wedge blades, the material particle contact with the heat transfer surface enough, it ensure the processing is stable.

Technical parameter

|

Model |

KJG-2.7 |

KJG-9 |

KJG-13 |

KJG-18 |

KJG-24 |

KJG-29 |

KJG-36 |

KJG-41 |

|

Heating area(m2) |

2.7 |

9 |

13 |

18 |

24 |

29 |

36 |

41 |

|

Volume(m3) |

0.06 |

0.32 |

0.59 |

1.09 |

1.53 |

1.85 |

2.42 |

2.8 |

|

Speed(rpm) |

15-30 |

10-25 |

10-25 |

10-20 |

10-20 |

10-20 |

10-20 |

10-20 |

|

Power (kw) |

2.2 |

4.0 |

5.5 |

7.5 |

11 |

11 |

15 |

15 |

|

Dimension A (mm) |

306 |

584 |

762 |

940 |

1118 |

1118 |

1296 |

1296 |

|

Dimension B(mm) |

736 |

841 |

1066 |

1320 |

1474 |

1474 |

1676 |

1676 |

|

Dimension C(mm) |

1956 |

2820 |

3048 |

3328 |

3454 |

4114 |

4115 |

4724 |

|

Dimension D (mm) |

2972 |

4876 |

5486 |

5918 |

6147 |

6808 |

6960 |

7570 |

|

Dimension E (mm) |

1752 |

2540 |

2768 |

3048 |

3150 |

3810 |

3810 |

4420 |

|

Dimension F (mm) |

380 |

380 |

534 |

610 |

762 |

762 |

915 |

915 |

|

Dimension G (mm) |

762 |

838 |

1092 |

1270 |

1524 |

1524 |

1778 |

1778 |

|

Medial inlet |

(2)3/4 |

(2)3/4 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

|

Medial outlet |

(2)3/4 |

(2)3/4 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |

(2) 1 |